MEDIUM PRESSURE FAN WITH RADIAL IMPELLER BELT DRIVE IN Fe360 SHEET

MANUFACTURING FEATURES:

• Fan made of Fe360 sheet. The fan paint finish is based on a Qualicoat polyester powder coating stoved at 200ºC, with an average film thickness of 70 microns. Average heat resistence of coating is 180ºC with peaks of 200ºC.

• Fully welded or joined housing.

• Impellers are painted with polyester primer that resists temperatures up to 300ºC.

• Motorized fan with basement (configuration 12). Full equipped fans including: motor, pulleys, belts, belts guard and shaft guard. Fitted over a base plate.

• Standard orientation: LG270.

• It allows adjusting the orientation locally at models 250 to 630. Models sizes 710 to 1000 size, orientation is fixed.

APPLICATIONS:

Designed for inline installation, they are suitable for:

• Industrial applications, extraction or injection of air.

• Cooling of machines and parts.

• Clean air and pneumatic transport.

• Solid material transport and textile fibers.

• Maximum working temperature: carried air: 130ºC, ambient 60ºC.

UNDER REQUEST

· Fans for 60Hz and special voltages.

· 2 speed motor.

· Fan with free shaft (configuration 1) or with motor supported on the pedestal side (configuration 9).

· C4 or C5 coating painting

· Hot dip galvanized

· Special steel (Cor-Ten A, Hardox...)

· Inox 304 (normal or electropolished finish)

· Inox 316 (normal or electropolished finish)

· Cooling wheel

· Anticaloric paint

· Reinforced housing

· Fully welded housing (waterproof)

· Insulated housing

· Split casing (for big sizes)

· Inspection door to facilitate maintenance and cleaning

· Drain plug.

· Airtight axle

· Frontal foot

· Double suction flange

· Available in the following versions:

- Non-sparking air passage and standard motor.

- ATEX II3GD Ex_na

- ATEX II3G Ex_e

- ATEX II3GD Ex_d

· Other brands of motors.

· Orientation: RD0, RD45, RD90, RD135, RD180, RD225, RD270, RD315, LG0, LG45, LG90, LG135, LG180. LG225, LG315.

| A | a | a1 | a2 | B | b | b1 | b2 | C | D | d | d1 | D1 | d2 | D2 | D3 | D4 | D5 | D6 | D7 | E | F | G | H | H1 | H2 | I | J | K | L | M | N | N1xØ1 | n1xp | N2xØ2 | n2xp | N4 | O | O6 | Ø3 | Ø4 | P | Q | R | R' | S | S | S1 | S2 | S3 | S4 | S5 | S6 | S7 | T | T1 | U | V | V1 | W | X | X | X1 | X2 | X3 | X4 | X5 | X6 | X7 | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 308 | 801 | 871 | 921 | 1565 | 569 | 639 | 689 | 1686 | 710 | 715 | 775 | 1171 | 815 | 1015 | 976 | 936 | 814 | 718 | 1330 | 1994 | 710 | 385 | 950 | 710 | 1180 | 1056 | 607 | 657 | 697 | 36 | 67 | Nº16 M10x30 | 2x200 | 14x14 | 3x200 | 45 | 607 | 620 | 19 | 20 | 657 | 140 | 45 | 67 | 976 | 976 | 814 | 718 | 710 | 1330 | 1171 | 1015 | 936 | 36 | 18 | 1056 | 1036 | 65 | 2164 | 814 | 814 | 710 | 1330 | 1171 | 1015 | 976 | 936 | 718 | 200 |

MANUFACTURING FEATURES

• For axial (inlet and outlet) and centrifugal (inlet) fans.

UNDER REQUEST

• Versions in stainless 304 and stainless 316.

MANUFACTURING FEATURES

• Flexible polyurethane coupling flange with fiberglass fabric to avoid possible vibrations to the installation.

• 160 mm width and supplied with 2 fixing clamps.

• Certified according to the European standard EN 12101-3 400ºC/2h. Fire classification: M0.

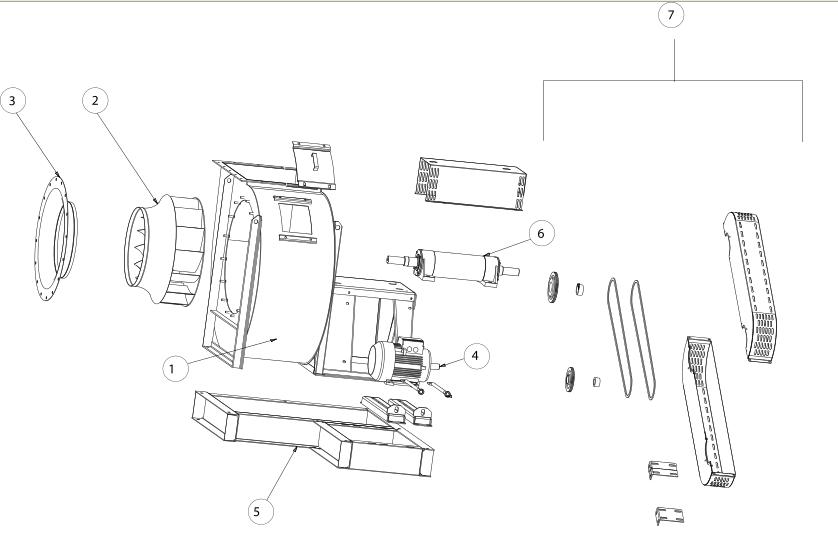

| Nº | Family | Name | Qty |

|---|---|---|---|

| 1 | TURBINE | MTZM 1000 P/R | x1 |

| 2 | INLET CONE | MBZM/MTZM 1000 P/R | x1 |

| 13 | PIECE TRANSMISSION | 150 | x1 |