HIGH PRESSURE DIRECT DRIVE FAN WITH BACKWARD CURVED IMPELLER IN CAST ALIMUNUM IN ROLLED STEEL SHEET HOUSING

MANUFACTURING FEATURES:

• Rolled steel sheet housing.

• Fully welded housing.

• High efficiency simple inlet backward impeller with self-cleaning system manufactured in cast aluminum.

• Polyester powder finishing coat.

• Standard asynchronous squirrel-cage motor with IP-55 protection and class F insulation. Standard voltages 230/400V 50Hz motors up to 4kW and 400/690V 50Hz for higher powers.

• Standard orientation: LG270

APPLICATIONS:

Designed for inline installation, they are suitable for:

• Industrial applications, extraction or injection of air.

• Cooling of machines and parts.

• Clean air transport.

• Exhaust after filters, separators and cyclones.

• Pneumatic transport.

• Maximum working temperature: carried air: 130ºC, ambient 60ºC.

UNDER REQUEST:

• 60Hz fans and special voltages.

• 2 speed motors.

• Orientation: LG0, LG45, LG90, LG135, LG180. LG225, LG315.

| A | B | B1 | C | D | E | F | G | H | I | J | KØ | L | M | N | O | P | QØ | R | S | TØ | UØ | V | Y | Z1Ø |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 877 | 716,5 | 307,25 | 121 | 358 | 520 | 150 | 200 | 583 | 275 | 325 | 258 | 589 | 614 | 256 | 206 | 246 | 292 | 162 | 280 | 11 | 210 | M6 | 548 | 11 |

MANUFACTURING FEATURES

• Safety start-stop switches according to IEC 60947-1 and IEC 60947-3.

• IP65 and always equipped an auxiliary contact.

• Useful for switching off the current before handling the fan.

*Máx. thermal current air (A)

MANUFACTURING FRATURES

• Inlet protection guard to avoid the entry of objects and contact with the impeller.

• Made of galvanised steel models 7,9, 10, 12 and 15. And the rest of models with polyester powder finishing coat.

MANUFACTURING FEATURES

• Connection to be fitted in the centrifugal fans outlet.

• Manufactured in galvanized steel.

UNDER REQUEST

• Versions in stainless 304 and stainless 316.

MANUFACTURING FEATURES

• Flexible polyurethane coupling flange with fiberglass fabric to avoid possible vibrations to the installation.

• 160 mm width and supplied with 2 fixing clamps.

• Certified according to the European standard EN 12101-3 400ºC/2h. Fire classification: M0.

MANUFACTURING FEATURES

• For axial (inlet and outlet) and centrifugal (inlet) fans.

UNDER REQUEST

• Versions in stainless 304 and stainless 316.

MANUFACTURING FEATURES

• Specially designed for speed frequency control in ventilation applications.

• Ultra compact, simple operation and wide range of functions.

*Dial panel incorporated. Optional EMC filter.

Certifications: CE/UL/CSA/EN/GOST/CCC.

Protection index IP20.

The selection of SFC frequency drive speed controller must be made based on the maximum intensity absorbed by the fan to be regulated. The powers (kW) and the intensity for constant load refer to the normal duty (150% overload for 60 seconds). The intensity for quadratic load admits an overload of 110% during 60s.

SFC 230: Entrance 230V I, exit 230V III

SFC 400: Entrance 400V III, exit 400V III

EMC filter incorporated for models from 47A (included)

*Lineal load rated current

**Quadratic load rated current

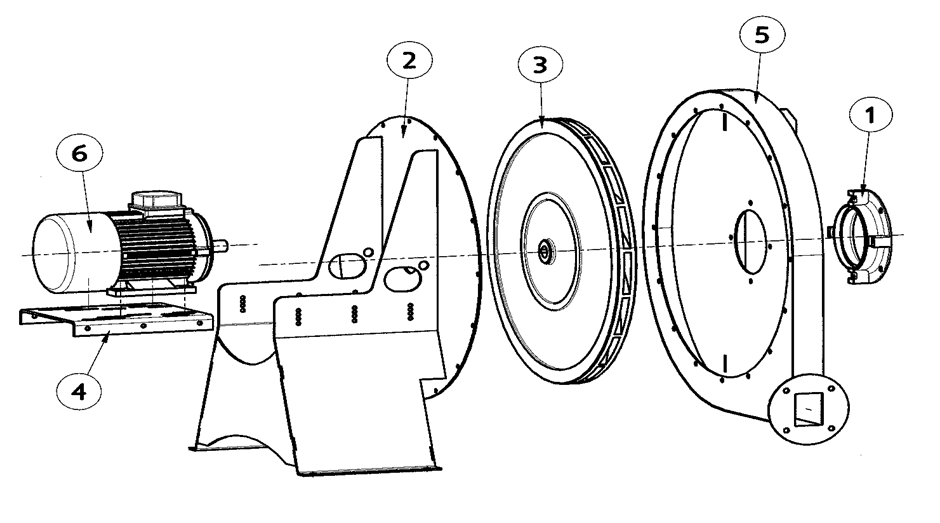

| Nº | Family | Name | Qty |

|---|---|---|---|

| 1 | INLET CONE | AA 50/5 | x1 |

| 2 | BASE SUPPORT MOTOR | AA50/5 | x1 |

| 3 | TURBINE | AA 50/5 T2 4kW LG | x1 |

| 4 | MOTOR SUPPORT | MBR-MBRF63,71,45P/R(B) | x1 |

| 5 | CASING | AA50/5 | x1 |

| 6 | MOTOR | 4KW T2 B3 230/400V | x1 |